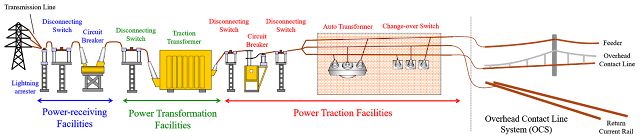

Traction Substation (SS)

A Traction Substation steps down an AC three-phase power supply to 25 kV, and converts the voltage to two single phases which are then supplied to the overhead contact line. The facilities in the SS are broadly classified into four categories, power-receiving facilities , power transformation facilities , power traction facilities , and remote control facilities. (1)The power-receiving facilities The power-receiving facilities include a power-receiving disconnecting switch , circuit breakers , lightning arresters , voltage transformers , and protective relays . Those facilities are installed for drawing and receiving power via two lines from a three-phase high-voltage bus line of a power company. (2)The power transformation facilities The power transformation facilities are configured from AC feeding transformers , disconnecting switches and operating transformers or other components. (3)The power traction facilities The power traction facilities are conf...